As a small kitchen appliance that is both entertaining and practical, the household marshmallow machine is entering more family scenes and becoming a popular choice for parent-child interactions and holiday gatherings. It transforms traditional street craftsmanship into a convenient home experience. With its compact size, simple operation and affordable price, it has gradually occupied a place in the small home appliance market.

1. Core Cognition: Working Principle and Core Components of home cotton candy machine

Working principle

The operating logic of the home cotton candy machine is simple and easy to understand. After the machine is started, the internal motor drives the sugar dispenser (sugar bin) to rotate at high speed. At the same time, the heating device heats up the sugar bin and melts the added sugar into liquid syrup. Under the action of centrifugal force, the syrup is thrown out of the small holes of the sugar dispenser. After rapid contact with the cold air from the outside, it instantly condenses into fine sugar filaments, which are collected by the rotation of the marshmallow stick to form fluffy and soft marshmallows.

Core component analysis

Sugar dispenser (sugar bin): As the "core heart" of the machine, it directly affects the thickness and fluffiness of the sugar shreds. The all-metal material is preferred, which is both durable and easy to clean. The hole size and distribution must be uniform and reasonable.

Heating device: Mainly divided into two categories: quartz tube heating and electric heating wire heating. The quartz tube heats evenly and has a long service life, but the preheating time is slightly longer; the electric heating wire heats and preheats quickly, but the heating uniformity and durability are slightly inferior.

Motor: The "power source" that provides rotational power. Power and speed are directly related to sugar production efficiency. Usually 450W-550W power and a speed of about 2800 rpm are golden configurations, which can not only ensure the speed of sugar production, but also control noise and power consumption.

Sugar-catching tray and anti-splash cover: The sugar-catching tray needs to be made of food-grade material. The larger the diameter and the deeper the depth, the easier it is to make large marshmallows; the anti-splash cover can effectively prevent sugar strands from splashing and keep the operating environment clean. It is a practical additional component.

2. Practical purchasing guide: Choose the right model based on your needs

Clarify usage scenarios and frequency

Occasionally used for family parent-child interaction and small gatherings, you can choose an entry-level model with basic functions and affordable price.

For frequent use or party display, it is recommended to choose a model with better materials, good heating uniformity, and exquisite appearance design.

Key buying points

Material safety: The core components must meet food-grade standards. The sugar dispenser is preferably made of all metal, and the sugar tray should be made of low-quality plastic that is easy to damage due to odor and odor.

Heating method: Focus on durability and heating uniformity and choose quartz tube heating; pursue high efficiency, convenience and fast sugar production and choose electric heating wire heating.

Operation and cleaning: Give priority to one-button control models to lower the threshold for use; the detachable design of parts can greatly improve cleaning convenience and avoid sugar residue residue.

Safety configuration: It must have safety features such as anti-scald casing and overheating protection, especially suitable for families with children.

Price range: The current mainstream prices in the market are concentrated in the mid- to low-end. You can choose according to your budget and needs, without blindly pursuing high-priced products.

3. Practical skills and safety precautions

Production steps

Preparation work: Choose fine-grained white sugar (or colored fruit-flavored sugar), and use special marshmallow sticks, bamboo skewers or paper sticks; make sure all food-contact parts are clean and free of residue before use.

Preheating start: Turn on the power and preheat for 3-5 minutes. After the heating device reaches a stable temperature, turn off the power and add an appropriate amount of sugar (to avoid excessive impact on sugar output).

Collect sugar shreds: Restart the machine. When the sugar shreds start to be thrown out, slowly rotate the marshmallow stick horizontally or vertically along the edge of the sugar plate to collect sugar shreds evenly.

Completion of storage: After the marshmallow reaches the ideal size, turn off the power and take it out, and clean the machine parts in time.

Safety and Maintenance Points

Avoid touching high-temperature parts. The sugar dispenser and heating device are extremely hot when the machine is working. Children need full adult supervision when operating.

It is forbidden to run the machine empty for a long time. After each use, the machine needs to be cooled down before disassembling and cleaning the parts to prevent burns.

Check the motor and circuit regularly to prevent moisture or foreign matter from entering the machine and affecting its service life.

Store in a dry and ventilated place, away from direct sunlight and high temperature environments, to prevent component aging.

4. Industry Trends and Industrial Ecology

Market development status

In recent years, the home cotton candy machine market has shown steady growth. This trend has benefited from the increase in home entertainment demand due to consumption upgrades, as well as the promotion of e-commerce channels and short video dissemination. Young parents attach great importance to parent-child interaction scenes, which has led to a continued increase in the demand for home cotton candy machines that are both fun and engaging, especially in the holiday gift market. From a regional perspective, the penetration rate in economically developed regions such as East China and South China is relatively high. At the same time, the demand for cost-effective household marshmallow machines in overseas markets is also gradually expanding.

Industrial supply chain and production characteristics

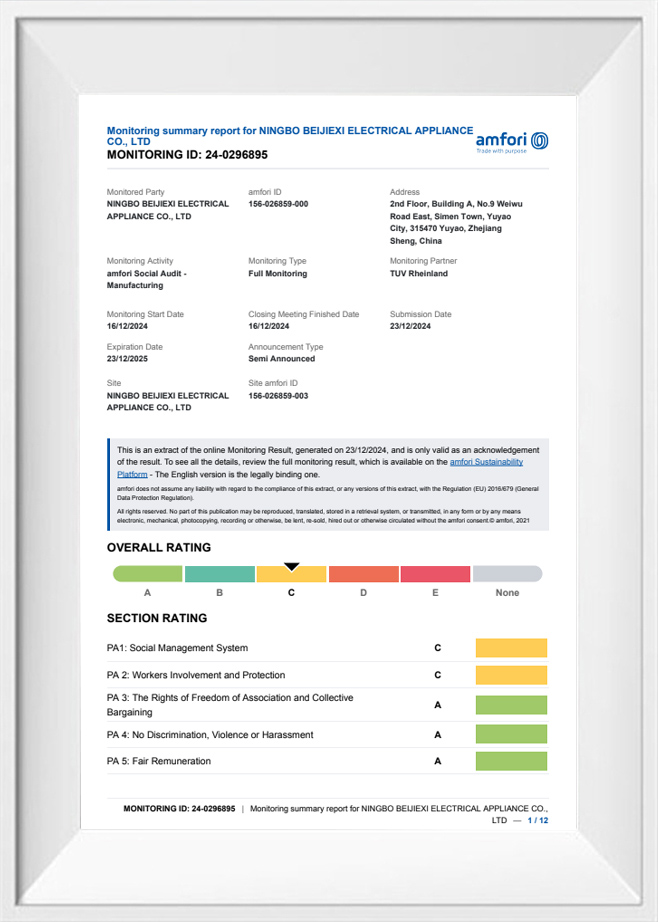

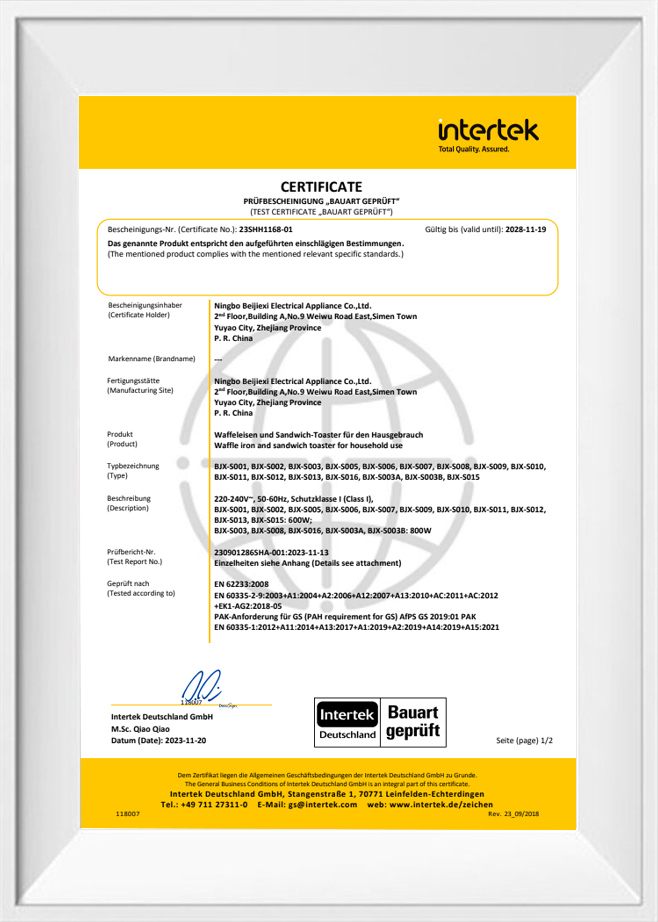

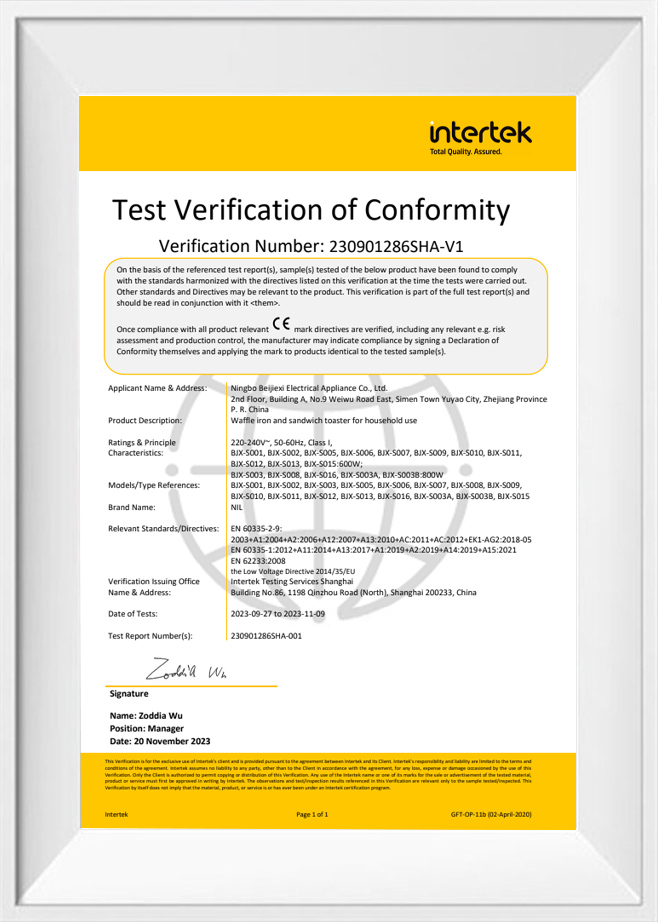

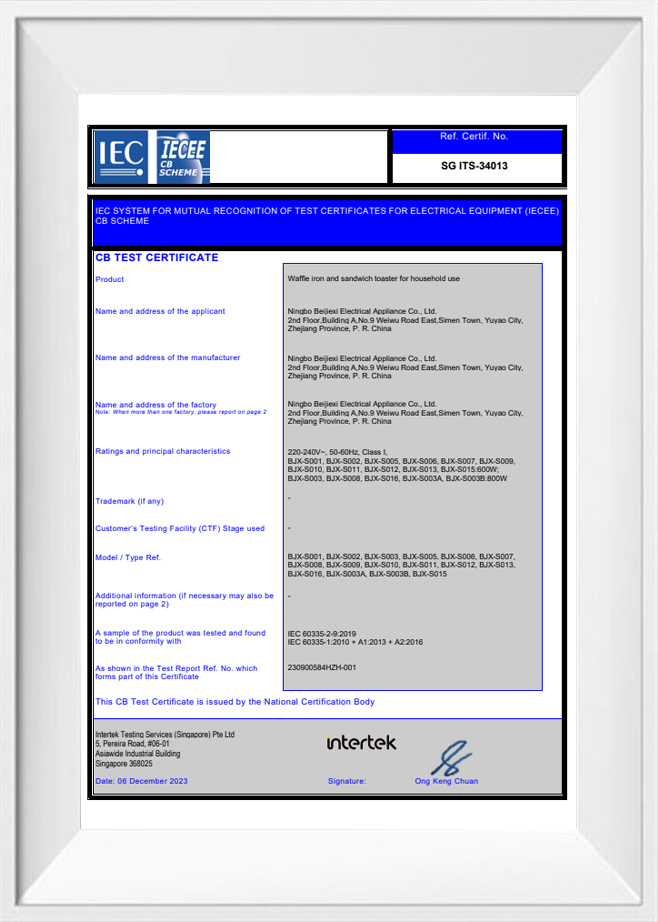

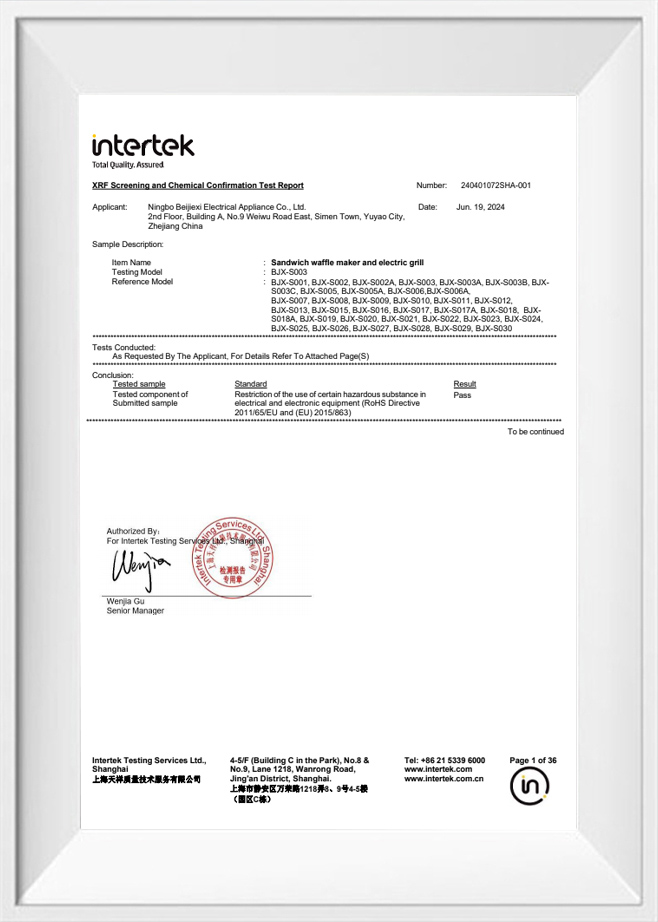

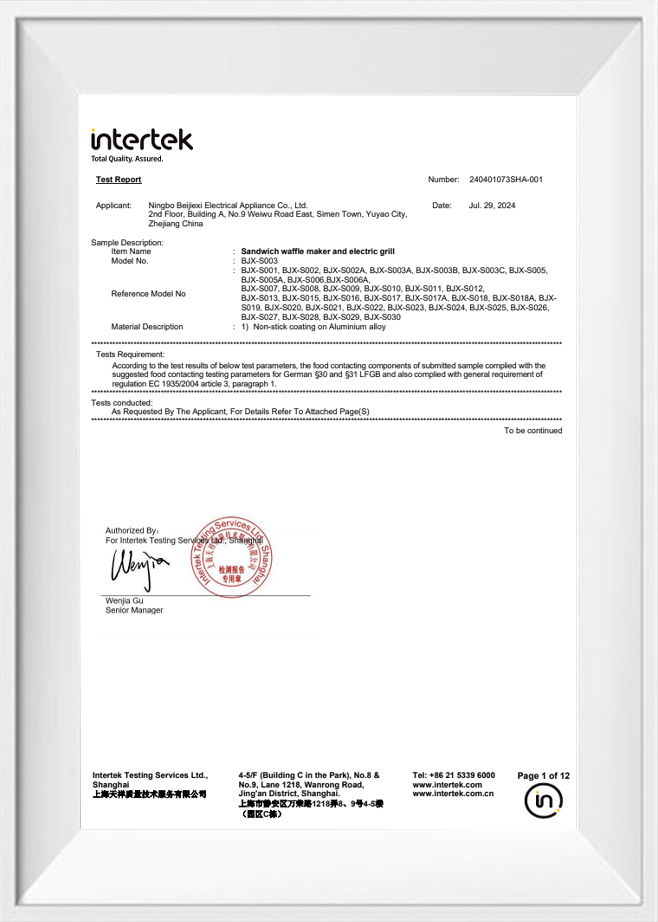

The production of household marshmallow machines involves multiple links such as mold manufacturing, injection molding, and component assembly, which places certain requirements on the comprehensive manufacturing capabilities of production companies. Ningbo Beijiexi is a professional manufacturer of kitchen appliances, located in Yuyao City, Ningbo. As a professional manufacturer of small kitchen appliances, the company not only covers marshmallow machines, but also has a variety of products such as sandwich machines, electric ovens, and popcorn machines. With its own mold workshop, injection molding workshop, and assembly production lines, it can provide one-stop services from design and development, mold manufacturing to production delivery, and provide the market with cost-effective products.

The existence of such enterprises has improved the industrial supply chain of household marshmallow machines, and their mature production system and export service capabilities have also promoted the circulation of products in the global market. At the same time, companies in the industry generally focus on cost control and quality improvement. By optimizing production processes and upgrading core component materials, they can improve the market competitiveness of products while meeting consumer needs.

Future development trends

Diversified functions: In the future, household marshmallow machines may add fruity sauce adding ports, sugar shred thickness adjustment, timing functions, etc. to meet consumers' personalized production needs.

Lightweight and beautiful design: The body will be smaller and more portable, while incorporating more fashionable colors and simple designs, adapting to modern home styles and taking into account both practicality and decoration.

Intelligent upgrade: Some mid-to-high-end models may add functions such as intelligent temperature control, APP control, and fault prompts to further reduce the difficulty of operation and improve the user experience.

Environmental protection and health: Use more energy-saving heating technology, match recyclable food contact parts, and guide consumers to use low-sugar and natural raw materials, in line with the concept of healthy consumption.

5. Frequently Asked Questions (FAQ)

Do marshmallows made with a household marshmallow machine taste bad? It may be that the sugar particles are too coarse, the heating temperature is insufficient, or the holes in the sugar dispenser are blocked. It is recommended to replace the fine sand, extend the preheating time, and clean the sugar dispenser promptly after use.

Does the machine make too much noise when working? There is a high probability that the motor is aging or the components are loose. Check the status of the motor and tighten the screws. If the problem still persists, contact after-sales service.

Candy sticks easily or cannot be shaped? It may be that the ambient humidity is too high or the amount of sugar added is too much. Choose a dry environment to operate and control the amount of sugar added to 5-10 grams each time.

The rise of household cotton candy machines is the epitome of the "entertainment-oriented and scene-oriented" trend in the small home appliance industry. Whether consumers are choosing products or companies are arranging production, they must focus on the core needs of "practicality, safety, and convenience." As technology upgrades and market demand iterates, this childlike small home appliance is expected to be implemented in more families and become an important carrier to enhance the happiness of life.

The world of grilling has evolved over the years, offering more options for cooking enthusiasts. While traditional grills have been a staple for many years, a newer appliance, the Grill Maker, has gained popularity for its convenience and versatility. 1. Convenience and Ease of U...

Read More

English

English  中文简体

中文简体  Español

Español  Deutsch

Deutsch