Home Popcorn Maker Industry Knowledge: Key Practical Questions Answered

Home popcorn makers have long been popular devices for home entertainment and small gatherings. But with diverse types, complex parameters, and numerous market options, do you still have many questions? This article compiles core industry knowledge, connected by practical questions, to help you fully understand home popcorn makers.

I. What are the mainstream types of home popcorn makers, and what are their respective features?

There are three main types of home popcorn makers on the market, each suitable for different needs. Hot air popcorn makers use hot air for heating, requiring no oil. They produce low-fat, healthy popcorn and are easy to operate, finishing in just a few minutes—ideal for health-conscious families. Microwave popcorn makers rely on microwave principles, heating corn kernels in a sealed container. They offer high automation and compatibility with various flavors like butter, salty, and sweet, suiting users who value convenience. Stovetop-style popcorn makers are the traditional type, using direct heating and needing oil. They make popcorn with a full texture and rich aroma but require some skill to control the heat.

The core differences between types lie in heating methods, health attributes, and operation difficulty. Choose based on your eating habits and usage scenarios.

II. What core parameters should not be ignored when buying a home popcorn maker?

Key parameters directly affect user experience—be sure to clarify these questions in advance. First, material safety: does the food-contact part use food-grade materials like 304 stainless steel to avoid harmful substance leakage? Second, capacity: mini models (around 100ml) are for 1-2 people, while large-capacity ones (over 200ml) are better for family gatherings or small commercial settings.

Ease of operation is also important: does it have a clear control panel for easy adjustment of heating time and temperature? Cleanliness is another key factor—fully sealed designs or non-stick liners significantly reduce cleaning effort. Additionally, safety cannot be overlooked: does it have anti-scald designs, safety locks, and automatic pressure relief functions to prevent accidents during use?

III. What is the working principle of a home popcorn maker, and what are its core components?

The seemingly simple popcorn-making process follows clear scientific logic. The core principle is that the heating element rapidly heats the moisture inside corn kernels into water vapor, creating high pressure that bursts the kernel shells and expands the starch into fluffy popcorn.

Core components include heating elements, stirring elements, corn kernel trays, control panels, and discharge ports. Heating elements—usually heating coils and plates—are the heat source. Stirring elements continuously flip kernels for even heating. Control panels adjust heating time, temperature, and stirring speed to meet different taste needs. The quality of these components directly determines popping efficiency and taste, serving as important criteria for product quality.

IV. What are the industry development trends of home popcorn makers, and how do manufacturers meet market demands?

With upgraded consumer demands, the industry is moving toward health, intelligence, and customization. Driven by health awareness, oil-free cooking technology is gaining attention, with devices increasingly supporting healthy oils and natural seasonings to align with low-fat, low-calorie consumption trends. In terms of intelligence, features like mobile app control, preset cooking programs, and recipe recommendations are becoming popular, enhancing user interaction.

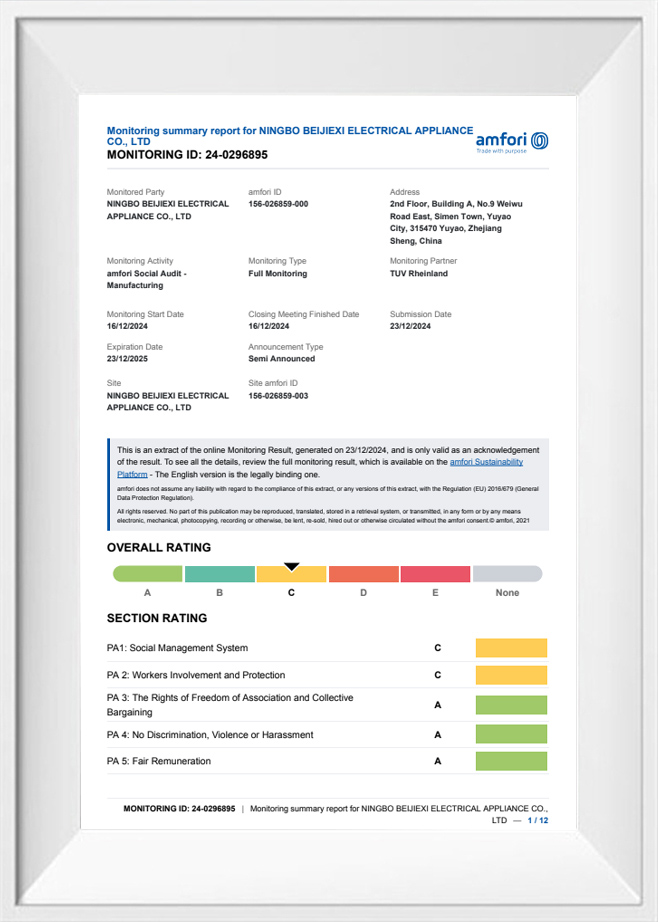

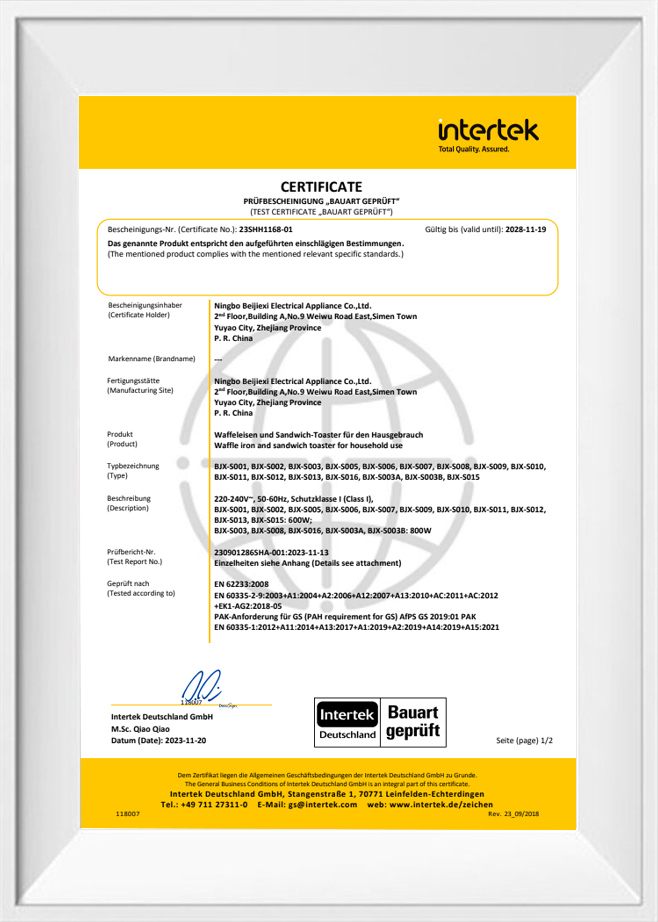

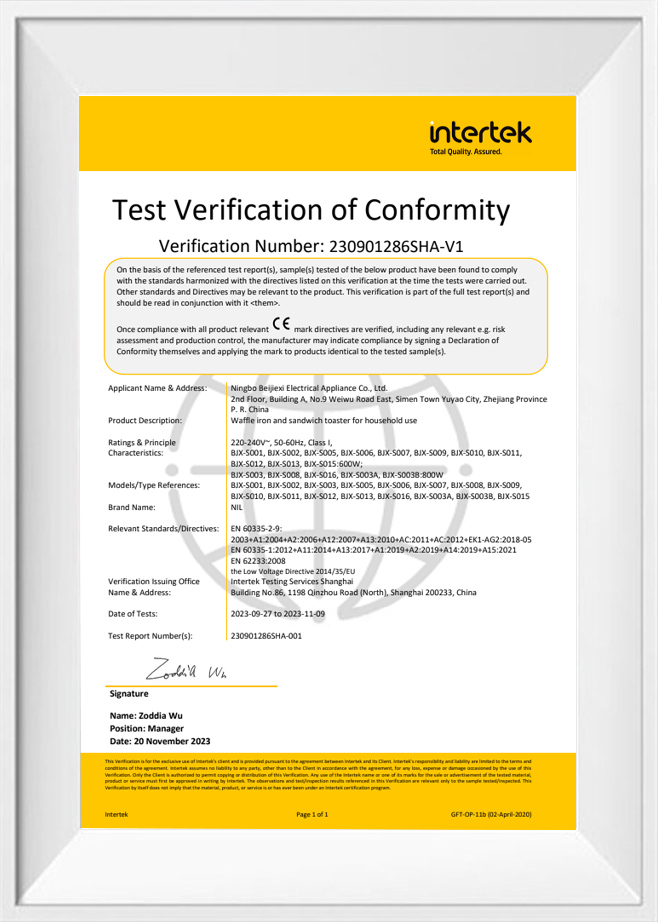

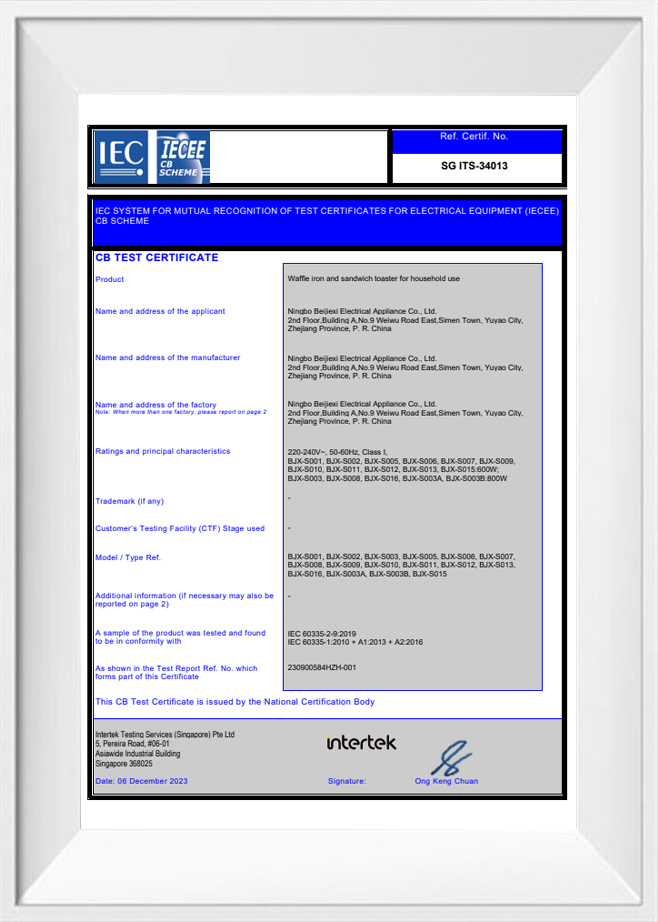

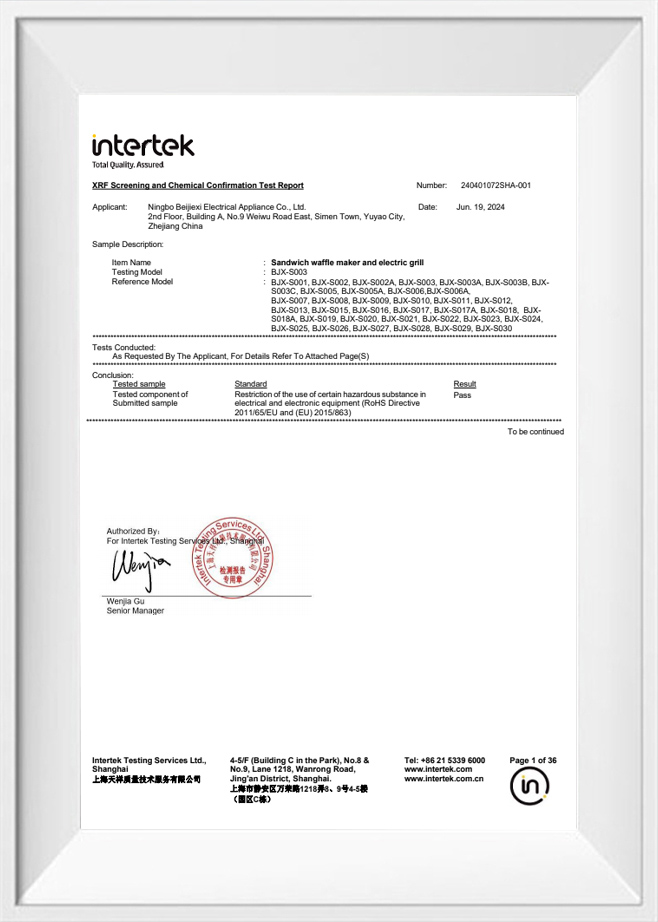

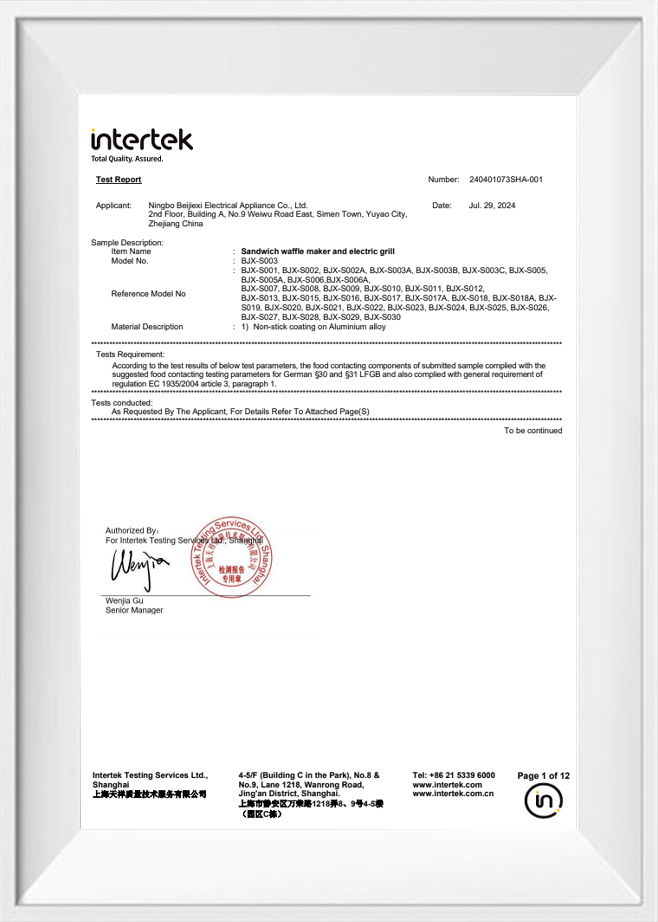

This trend has prompted manufacturers to continuously upgrade production capabilities. Founded in September 2014, Ningbo Beijiexi Electrical Appliance Co., Ltd. is a leading China small kitchen appliances manufacturer and wholesale factory located in Yuyao City, Ningbo. With a production base of over 5,000 square meters, professional mold and injection molding workshops, and complete assembly lines, it achieves efficient production of popcorn makers. Boasting 50 skilled workers and an exclusive testing laboratory, the company leverages its strong R&D team to ensure product quality and customize development based on customer drawings or samples. It provides one-stop services from design, R&D, mold making, tooling manufacturing, and production follow-up to export and delivery to warehouses worldwide, accurately meeting market demands for high-quality, customized products. Its featured product range also includes sandwich machines, electric grill machines, coffee machines, and cotton candy machines.

V. What practical tips are there for using and maintaining a home popcorn maker?

Proper use and maintenance extend device lifespan—pay attention to these details. Should you preheat before use? Preheating time varies by type, usually 1-3 minutes. Sufficient preheating ensures a higher popping rate. How to balance the ratio of corn kernels to seasonings? Generally, the ratio of corn kernels to oil is about 5:1. Add seasonings to taste to avoid affecting texture or damaging the device.

For maintenance, clean the device only after it cools completely—never rinse with water while hot to prevent component damage. For devices with mold and injection molding structures, regularly check sealing performance and stirring element flexibility, repairing abnormalities promptly. When not in use for a long time, dry the device and store it in a cool, ventilated place to prevent moisture and rust.

The world of grilling has evolved over the years, offering more options for cooking enthusiasts. While traditional grills have been a staple for many years, a newer appliance, the Grill Maker, has gained popularity for its convenience and versatility. 1. Convenience and Ease of U...

Read More

English

English  中文简体

中文简体  Español

Español  Deutsch

Deutsch